21.02.2014

Case Study: Bonding Failure on a Composite Structure

A supply chain is an organism. For an organism to thrive, each part—cells, organelles, atoms—must work together. A supply chain’s health relies on communication at all levels and steps. Each part must work intimately, so that even the smallest problems are not only caught and corrected, but also avoided in the future, thus optimizing yield and driving out cost.

Consider the following case:

Problem

Optimum Design Associates assembles electronics into a carbon fiber enclosure for a major aerospace manufacturer. The enclosure's structure is formed by bonding two carbon fiber pieces to an aluminum heat seak. During thermal cycling the bonds between carbon fiber and aluminum began to fail, resulting in a 70% rejection rate. The cause was not immediately clear since bonds passed incoming inspection but failed post assembly during final test thermal cycling. This was a major problem because late component failure meant heavy rework. Not only was the source of the adhesive’s problem unexpected, but Optimum and our supplier had a stream of work in process that was delayed.

Root Cause Analysis

Optimum is located in the San Francisco Bay Area and the supplier is in the Midwest. Using data, photos and videos exchanged by email, engineers from both parties worked together to understand the failure point and isolate the root cause. By systemically eliminating various potentials, the team identified the bonding tape as the primary root cause, and the application method as a potential contributor. They then agreed on a process to test bonding alternates:

Test Scope:

1. Bond 1’’x 4’’ carbon strips together using different adhesive tape and 3M recommended procedure.

2 Thermal Cycling: 60min 0F, 45min 212F, cool to room temperature.

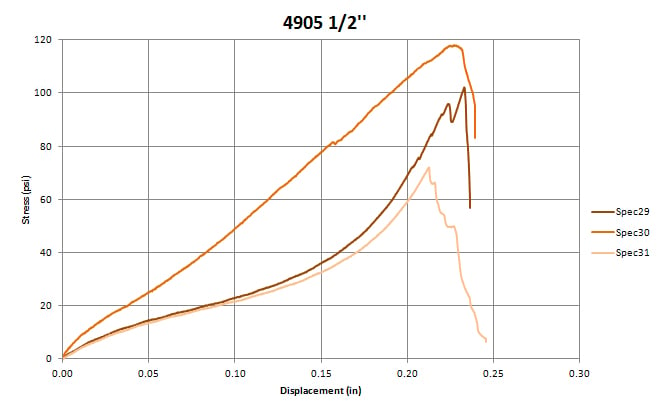

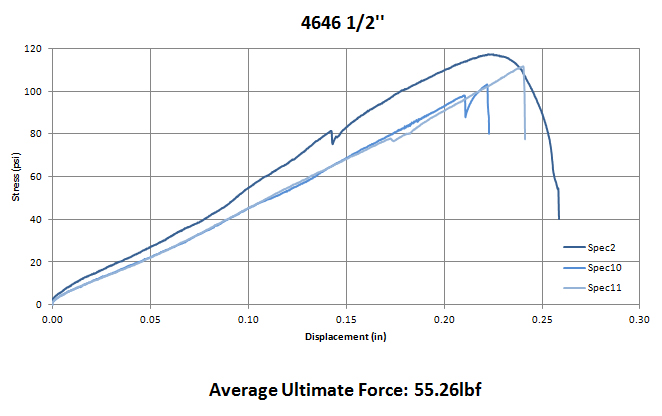

3. Mechanically test adhesive tape by applying shear loads until failure.

4. Repeat the testing on 4 different adhesives to identify best adhesive tape for the application.

Coupon Assembly Procedure

1. Clean surface for sanding

2. Sand coupon surface with 120grit sandpaper

3. Clean coupon with isopropyl alcohol

4. Apply adhesive tape

5. Join coupon

6. Apply pressure to adhesive using hand roller

7. Allow sample to cure at least 24 hours

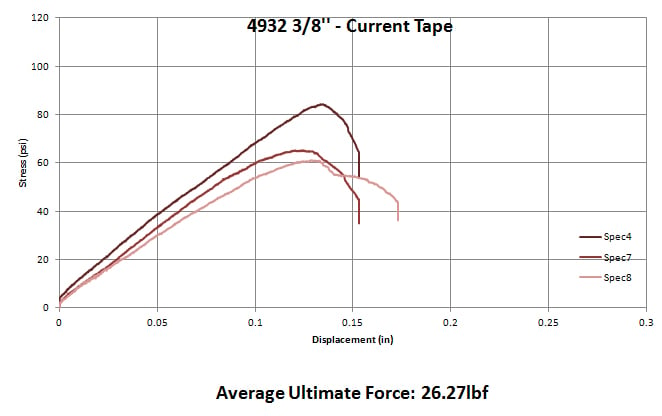

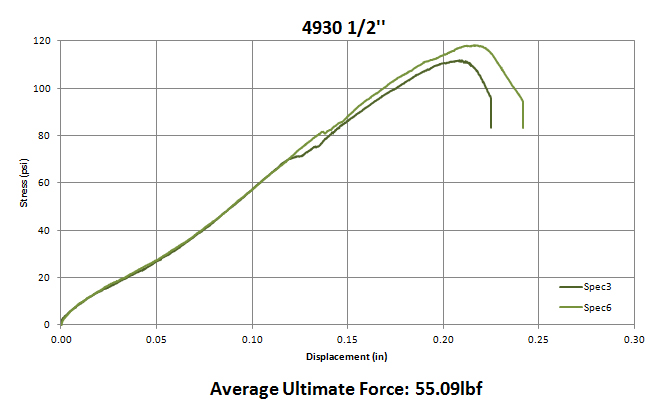

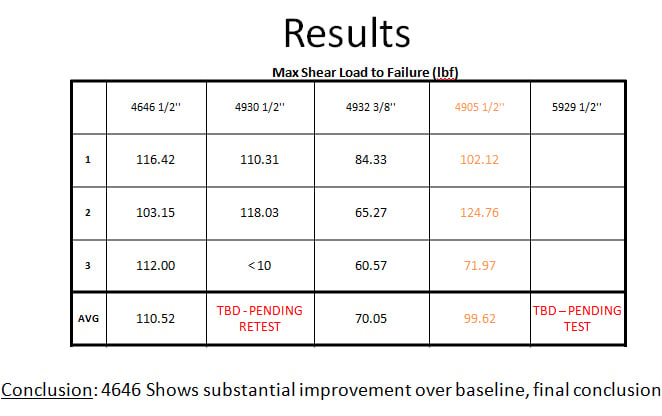

From this procedure the following test results were logged for various adhesives:

Corrective Actions

The team next put together a detailed 20-step rework instruction with photos documenting each step. The supplier flew a team to Optimum's factory to assist with rework of onsite inventory.

Preventative Actions

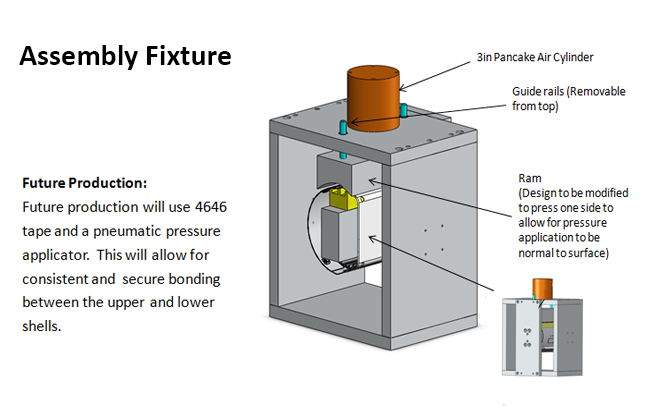

In addition to changing the bonding material, the bonding process was also improved by developing a custom fabricated fixutre. CAD drawings were made and reviewed, and the fixture was fabricated at a machine shop.

Maintaining a diligent and thorough exchange of information, the collaboration proved to be so quick, thorough and creative, rework didn’t require complete dismantling and reassembly. In the end, the product was delivered to the customer with minimal schedule distruption, and the overall product’s design was improved.

Summary:

- Optimum found problems with customer-specificed bonding.

- Optimum worked intimately with supplier to narrow down the problem.

- The problem was found and corrected, and rework was completed on existing failing units.

- With smart and assertive information transfer, collaboration, and problem-solving the downstream problems were limited, and Optimum contributed improving their customer’s product.

Conclusion

The case confirms that with close supplier collaboration, problems can be resolved quickly without disturbing the end customer's resources or schedule. Measures were successfully taken both to fix the existing defective parts and refine the manufacturing processes to ensure the problem was prevented in the future.

While maintaining proactive processes are crucial, assertive reactive processes are sometimes necessary. In the rare event errors aren’t prevented, know how to react effectively. This means knowing how to work with both your suppliers and customers. Like a thriving organism, a supply chain is greater than the sum of its parts. As one of the staff members involved in the case later commented: “You must understand not just your portion of the production process. Understand each process before and after your step.”