10.07.2014

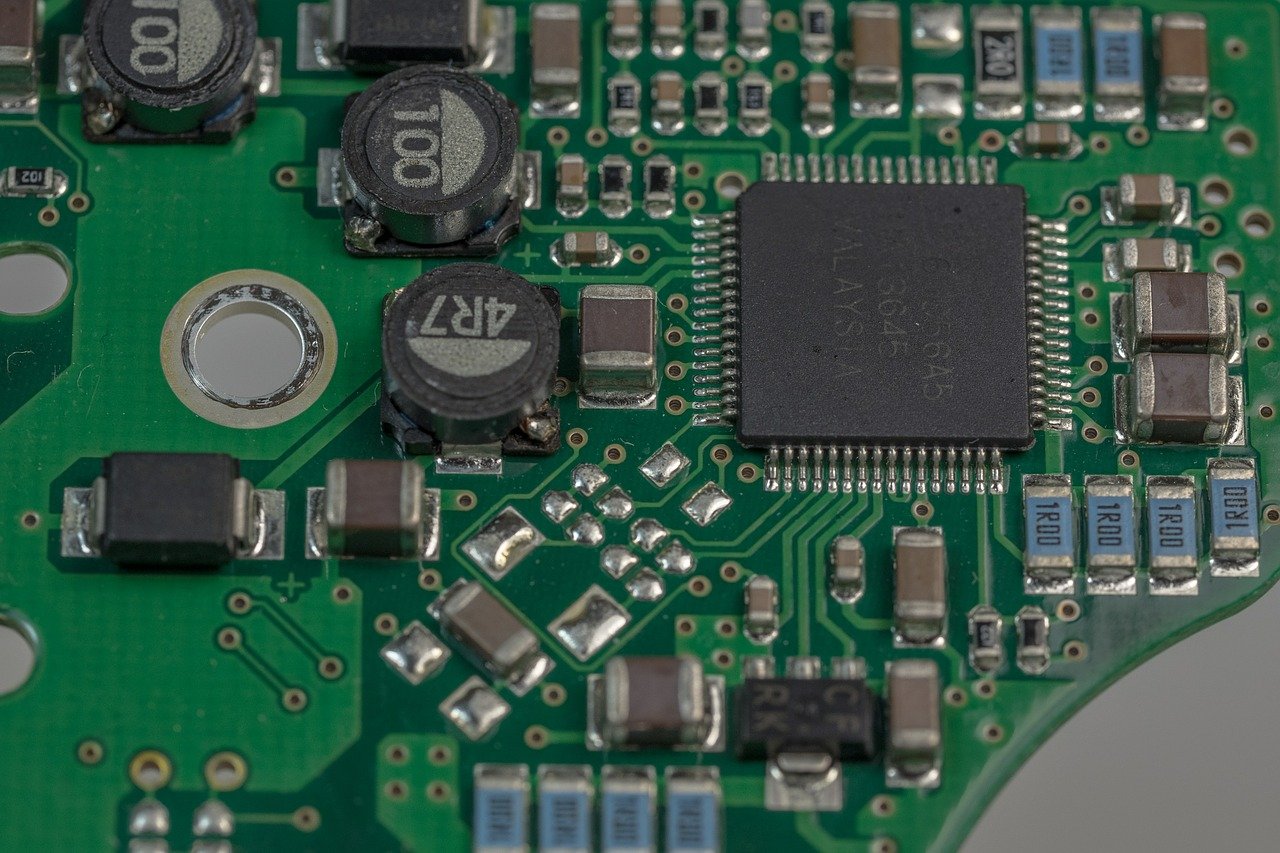

PCB Design Tips: 5 Need-to-Know Component Assembly Methods

Part of a designer's professional developments should be to learn as much as possible about the activities that go before and come after the layout process. And with today's highly complex designs, the assembly process has grown in importance and has become a major concern for designers.

A basic understanding of the assembly step is to know the various ways in which the components are attached to the board. These methods depend on the type of components (thru-hole or SMD) and their location (one side or two sides). The combinations of the component types and location are as follows, along with the associated assembly methods:

| Thru-hole (one side) |

Kit, Auto Insert, Semi-Auto Insert, Hand Insert, Wave Solder, Clean, Post- Wave Assembly, Test |

| SMD (one side) |

Kit, Print Solder Paste, Auto Place, Reflow, Clean, Test |

| Mixed (one side) |

Kit SMD Parts, Print Solder Paste, Auto Place Reflow, Clean, Kit Thru-Hole Parts, Auto/Hand Insert, Wave Solder, Clean, Test |

| SMD (two side kit) |

Top-Side SMD Parts, Print Solder Paste, Auto Place, Reflow, Clean, Kit Bottom-Side SMD Parts, Print Solder Paste, Auto Place, Reflow, Clean, Test

|

|

Thru-hole (oneside); SMD (two sides) |

Kit Top-Side SMD Parts, Print Solder Paste, Auto Place, Reflow, Clean, Kit Bottom-Side SMD Parts, Print Solder Paste, Auto Place, Reflow, Clean, Kit Thru-Hole Parts, Auto/Hand Insert, Wave Solder, Clean, Test |

Understanding these key characteristics not only improves the quality of a PCB design, but also streamlines the DFM process, which ultimately reduces the chances of having the design sent back for rework. A first-rate design incorporates each of these when necessary.

There are many more assembly issues that can affect the PCB designer. As they become documented, they will be added to this list. Designers, however, are encouraged to continually seek out information that will enable them to increase their ability to serve the customer.

![Download Optimum's Designer Handbook! [PDF format]](https://no-cache.hubspot.com/cta/default/317720/240d1413-c945-4cb8-a546-a84937b16039.png)