18.02.2021

PCOLA/SOQ Explained

The objective of PCBA manufacturing is to attach correct, working, and properly oriented components to their intended locations with connections that are formed to establish reliable mechanical and electrical connectivity. A defect is defined as "an unacceptable deviation from a norm," where unacceptable means action is required to repair or scrap, or to adjust process. Taken together, we can define PCBA manufacturing defects as an unacceptable mounting or solder joint that deviates from the norm enough to require rework, scrap, or process change.

A fault is a condition that causes a malfunction or failure. Defects can lead to faults, but not necessarily. Faults cannot cause defects. The goal is to eliminate manufacturing defects as a cause of faults.

The Defect Spectrum

In the mid 1990s Agilent defined a method called PCOLA/SOQ to categorize and score defects. The defect spectrum and description of their basic meanings is:

PCOLA - Attributes of the component

Presence - is the part there?

Correctness - is it the correct part?

Orientation - is the part oriented properly?

Live - does the part "come alive"?

Alignment - is it centered on pad properly?

SOQ - Attributes of the solder joint

Shorts - are there any shorts?

Opens - are there any opens?

Quality - consistent with relevant standard

Defect Coverage Scoring

Defect coverage can be defined as the ratio of detectable defects to the total number of defects. PCOLA/SOQ assigns a coverage value of 1, .5, or 0 to indicate the ability of a test process to evaluate for a particular defect. A complete test can be seen as the sum of many individual experiments. By assigning a graded value to each individual experiment, the test engineer can get a view of the overall test coverage.

- 1 indicates complete coverage at full confidence

- .5 indicates partial coverage with some chance of defect escape

- 0 indicates no test coverage whatsoever

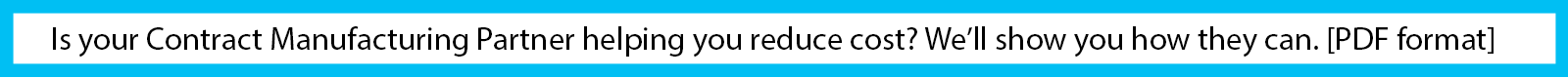

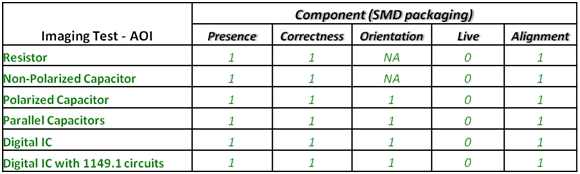

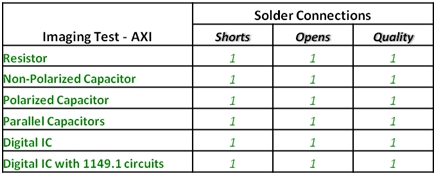

Below are PCOLA scores for AOI and AXI using a theoretical PCBA:

Since neither AOI or AXI apply power they are not capable of testing for Live. Notice that by applying both tests to this theoretical example we achieve complete coverage of the component attribute defect spectrum, except for Live.

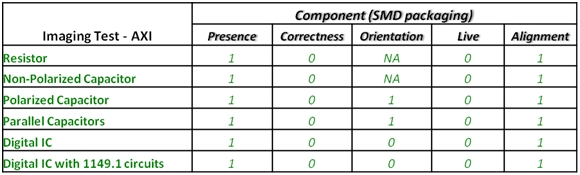

Here are the SOQ scores for AOI and AXI on the same example:

In this simplified example both tests have the same coverage. If we included BGAs or other components with non-visible solder joints, AXI would have better coverage than AOI.

The Fault Spectrum

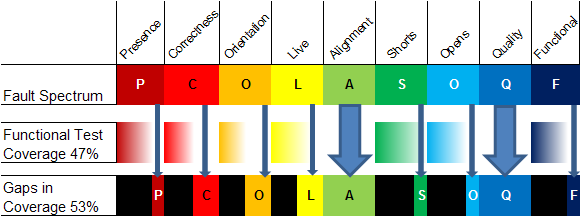

Our ultimate objective is to minimize faults by eliminating manufacturing defects. The effect of PCOLA/SOQ defect testing on the fault spectrum can be demonstrated with the following example.

Remember that defects do not necessarily cause faults. In this example the board undergoes functional test only, no prior inspection. The board potentially passes functional test with 53% of the defect universe untested. For example, this board may function but contain misaligned components (Alignment) or improperly formed solder joints (Quality) that may fail in the field, exponentially increasing costs.

Further, faults at functional test are notoriously difficult to diagnose, often requiring a more highly skilled and more expensive resource to correct. Defects, on the other hand, are very specific to a component or solder joint and are quite easy to correct.

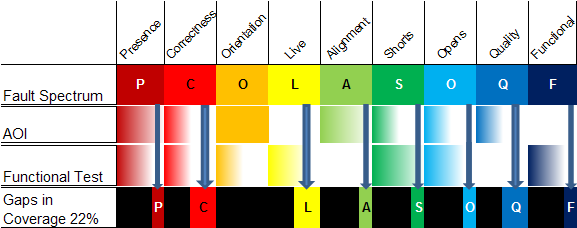

We can see that by adding just AOI, we reduce the coverage gap to 22%. Adding AXI and Flying Probe can reduce the gap to below 1%, virtually eliminating manufacturing defect-related debugging related to functional test faults and exponentially reducing the chances of manufacturing defect-related field failures.

Conclusion

PCOLA/SOQ's rigorous method of analyzing PCBA manufacturing test to categorize and score the possible defect universe can be used to develop a test strategy encompassing a larger portion of the defect universe by:

- Creating a definition of the overall defect universe.

- Identifying where gaps in coverage may occur.

- Choose appropriate complementary tests to ensure efficient coverage.

- Reduce faults discovered at functional test.

- Minimize rework costs.

- Minimize latent field failures.

Further Reading: What is World Class for Solder Joint DPMO?

This post originally appeared on the DigiSource Blog