10.07.2014

Outsourcing PCB Design: A Primer

Deciding to outsource a PCB design can be a daunting task. Between choosing a design firm to handle the design, knowing what to give them in terms of inputs, ensuring the design meets your specifications, there are myriad opportunities for a problem to arise. Upon deciding who you will be outsourcing the design too, the creation process begins. There are a number of critical steps which must be met for successful completion of a design. Here we’ll try and provide insight to the design process, as well as what is required of both the customer and designer at major milestones within the process.

Design Process Stages

- Initial Design Review & Integration

- Mechanical Definition

- Placement & Review

- Routing

- Pre-Delivery Review

- Wrap-Up

Design Review & Integration

This step of the process entails discussion with your PCB designer and your design engineers regarding their specifications and requirements, as well as assembling the necessary preliminary information to begin the design. Having an increased understanding of your customer’s requirements allows for a smoother design flow and makes following the later steps in the design process considerably easier.

Integration means adding intelligence to the PCB database, by means of either a netlist or schematic. This data must be provided to the board designer by your design engineer. Generally speaking, schematic integration can only occur within the same EDA product family, such as Mentor’s DxDesigner and Expedition. Netlist integration is still the most common means of attaching intelligence to your design. In many cases the netlist provided by an engineer will need to be translated into a format readable by EDA tools, either using macros in Microsoft Excel or Word, or a third party tool such as Omninet.

Mechanical Definition

Mechanical definition of the board occurs before any parts are placed, and entails the creation of the mechanical outline of the board, as well as any necessary mounting and tooling holes, fiducials, and keep-in and keep-out areas on the board. It is essential that this information is entered accurately, as errors could result in a sub-assembly that will not fit in the allocated space. The design firm must be provided accurately dimensioned mechanical drawings of the board enclosure in order to ensure that your requirements are met.

Placement & Review

Placement is arguably the most critical portion of the entire design process. A successful placement will meet both electrical and mechanical requirements of the design. Considering the overall importance of this step in the design process, we’ll be looking at electrical and mechanical placement separately.

Electrical component placement begins for the designer at the design review stage, and entails the designer familiarizing himself with the schematic, net rules, component application notes, and floor plan (if provided by the customer). Components are loosely grouped into types, and placed according.

- Fixed Components: Mechanically defined components such as connectors are placed first, as the designer has no input regarding their positioning, and critical signals will likely be traveling through these components.

- Interface Components: These generally represent groups of components, such as an Ethernet circuit, which has outputs tied to connectors, fingers, headers, or other off-board sources or destinations.

- Primary Active Components: Now the primary components of the board, such as processors, FPGAs, etc, are placed. Many other components will surround these parts, so it is important to place them while the board is still comparatively empty.

- Remaining Active Components: With the primary components placed, the remaining active components are placed about the board. This includes clocks, memory buffers, memory, oscillators, and other ICs.

- Review Placement: At this stage in the placement process the design should be sent back to the customer for placement review. This ensures that the design is moving in the right direction and all parties are satisfied.

- Place Remaining Components: Upon approval of the existing placement, the remaining passive components such as resistors and capacitors are placed on the board, and placement is effectively complete.

- Final Placement Review: Once all of the components have been placed, the board is again sent out for a final placement review.

Placement for manufacturing means that the design meets all of the physical assembly requirements presented. There are a number of common issues which can plague a design when placing components. Here is a list of mechanical placement considerations:

- Part-To-Board-Edge Clearance: There must be adequate space for the conveyor which moves the board along the transport system to hold onto the board, as a general rule top side components on the long side of the board should be clear from the edge by .120” (3mm), and .200” (5mm) on the bottom side.

- Part-To-Part Clearance: Placing components too close to each other can create difficulties in assembly for pick and place machines and the like. Always keep in mind your minimum component spacing in order to avoid these issues.

- Shadowing: Adjacent components with a large difference in height can also cause assembly difficulty, as the larger parts can block solder and heat from the smaller ones, leading to unstable connections on the board. Keeping these height differences in mind during placement allows for minimal shadowing.

- Part Orientation: Part orientation during placement has two primary goals. The first is to keep like components on the same rotation whenever possible (ODA preference is no more than two 45 degree rotations). Bottom side components should also be optimally oriented for how they will enter a wave soldering machine.

- Bottom-Side Components: If a design requires SMT components on the bottom of the board, performance issues must be weight against process issues. The following chart (ODADH pg 45) illustrates some approved bottom-side component placements.

Routing

Pending approval of placement, the board is now ready to be routed. By taking routing lanes into consideration during placement, routing is dramatically simplified. Comparable to placement of components about the board, routing is best accomplished by breaking the process into a series of steps. Again, an abbreviated look into each of these steps will be presented below.

- Routing Parameter Data Entry: Data, such as layer stack-up, trace width (impedance), via type, net ordering, pairs, and signal timing, is entered into your EDA tool of choice. If allowed and required by the design engineer, pin and gate swapping should occur at the same time as this step.

- Fanout: SMD devices should now be fanned out for internal traces. Most modern designs feature minimal top and bottom layer routing, with the exception of fanout traces used to route the signals down to internal layers.

- ICT Review: If In Circuit Test is required, now test point placement for probability of coverage should be reviewed. Requirements will vary by design; whether every net or just critical require a test point, etc. Reviewing these requirements with the engineer before the majority of the board is routed will allow for simpler test point placement later in the routing flow.

- Plane Shape Entry: Once test points have been reviewed, plane shapes for the various power and signal layers required by the board are included.

- Critical Route and Review: At this phase in the routing process, critical and interactive signals for the board are routed. Off-board interface connections, analog circuitry, very short routes, regular pattern flows (ex. Memory areas), are all hand routed. Once these signals have been routed, is a good time to send the design off for review.

- General Routing: Pending approval of the already completed routing, the remainder of open nets should be routed. It is possible to use an auto-router at this phase in the design, although that may not be appropriate for every design. Naturally, if an auto-router is not the ideal tool for the job, the remaining nets should be hand routed in the same fashion as the critical nets.

- Route Cleanup: Routing of the board is now nearly complete. The designer should visually inspect each layer of the design for cleanliness and manufacturability, as well as compliance with any rules provided by the design engineer. Any required ICT test points are now placed on necessary nets, and plane shapes are cleaned up and reviewed.

Pre-Delivery Review

Once the board has been fully routed, a Design Rule Check (DRC) is run to help ensure that the design as it stands adheres to all requirements put forth by you. This process compares lists of rules concerning the data in the design, and outputs error reports, giving the designer a very good idea of where problems with the board originate. Modern CAD tools generally utilize one of two forms of DRC, online (or dynamic), and batch DRC. The general difference between the two is that online DRC rules may be changed at any point during the design, and changes which violate a rule are not implemented, whereas a batch DRC is run near completion of the design at the request of the board designer. Here is a rundown of what each form of DRC generally checks (specifics may vary based on CAD tool used).

Online DRC

o Components – Parts and their rotation.

o Opens – Fanouts and nets.

o Traces – Widths, pad entry, and restricted layers.

o Via – Size and maximum count.

o Grids – Via and traces.

o Lengths – Maximum, minimum, matched, delay lengths, and stubs.

o Differential Pair – Length matching and delays.

o Crosstalk – Parallelism and estimated crosstalk.

Batch DRC

o Proximity – Spatial checking of elements to elements.

o Hangers – Trace stubs not required for connectivity.

o Trace Loops.

o Plane Violations – Check for connectivity and proper pour.

o Dangling Vias & Jumpers – Vias and jumpers not part of connectivity path.

o Unplated connecting pins.

o Vias and test points under parts.

o Minimum annular ring.

o Missing Pads – On soldermask, pastemask, and conductive layers.

The process of running DRC is relatively simple, however, the changes necessary to remove all errors from DRC may not be. If the designer feels rules are satisfied after running an initial DRC, and there are no new errors, then a second DRC check may be run to make sure DRC is satisfactory. “Satisfactory” is ultimately a broad word in the context of PCB design, but slight ambiguity is necessary. DRC may identify items as errors which are in actuality correct, and these “false negatives” may be disregarded by the designer. Flagged items may also violate a design rule for reasons which are acceptable, for example a placement proximity warning on a board edge connector. For any item flagged as an error by DRC, which is to be disregarded, the designer must be able to identify and explain the reasoning behind the decision to ignore the error warning.

Wrap –Up

At this stage in the process the design is fully routed, and submitted to the design engineer for final review. Final processing and clean up of the design will be necessary, but changes to the board should be minimal. Again, there are two primary steps to this phase of the design process; cleaning up of the labeling and drawings, and final review and shipping of outputs.

Updating the labeling and drawings ultimately entails a sanity check of the silkscreen, fabrication, and assembly layers, and updating of the film common and necessary artwork. Silkscreen text orientation and position should be arranged in a clear and legible manner, in order to simplify assembly. The assembly drawing should be similarly adjusted, including any necessary notes or instructions and an updated title block. A fabrication drawing should be created, which includes all dimensioning of the board, layer stack-up, drill chart, and updated notes and title block information. The title block of the film common must also be updated to reflect the current design. Any reference designators that have been modified should be renumbered during this step as well, and a WAS/IS list created for reference by the engineer and designer.

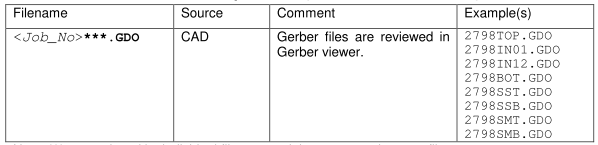

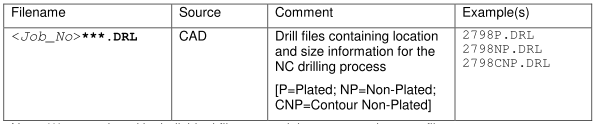

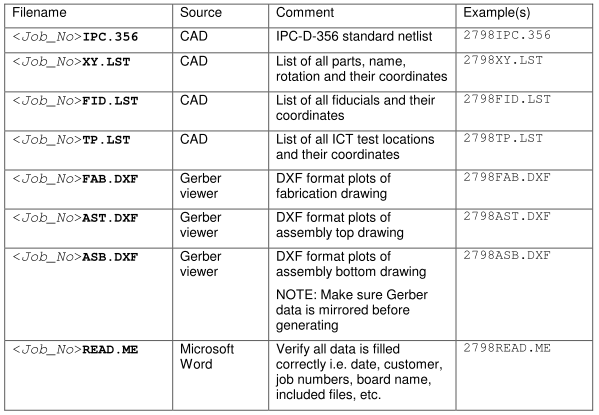

Once the necessary drawings have been generated and edited for use by the fabrication and assembly shops, the design is sent for a final review. Pending approval of this review, outputs are generated. This is the deliverable portion of the design, so ensuring that everything necessary for creation of the physical board is shipped to the customer is critical. Optimum Design Associates recommends ODB++ files as the preferred output for the design. ODB++ stores data in a hierarchical structure, and allows for more complete data than Gerbers in a single output file. Additional data includes the stack-up, bill of materials, component placement, and dimensional and fabrication data. ODB++ is widely adopted and accepted by all PCB suppliers. If ODB++ is inappropriate for your environment, the following output files are generated:

Trace, Screen, and Mask Files

Drill Files

Miscellaneous Output Files

As you can see, moving a design from a schematic to a completed board is a complex process involving many steps for successful completion. The easiest thing a customer can do to streamline the design process is communicate effectively with your design firm, both in terms of providing high quality inputs, and setting clear milestones for both review and delivery. This ensures that the design is completed in a timely matter, and any concerns and questions can be addressed before the board hits production.

Further Reading: How Are PCB Layout Jobs Priced?

![Download Optimum's Designer Handbook! [PDF format]](https://no-cache.hubspot.com/cta/default/317720/240d1413-c945-4cb8-a546-a84937b16039.png)